When culverts reach the end of their service life, one of the most common intervention strategies is to install a liner or slip-lining system. Although this inevitably reduces the internal diameter, it often surprises people that flow performance can actually improve. For civil and structural engineers working on Network Rail infrastructure, the reasons behind this are firmly rooted in hydraulic physics, material selection, and the behavior of roughness within confined flows.

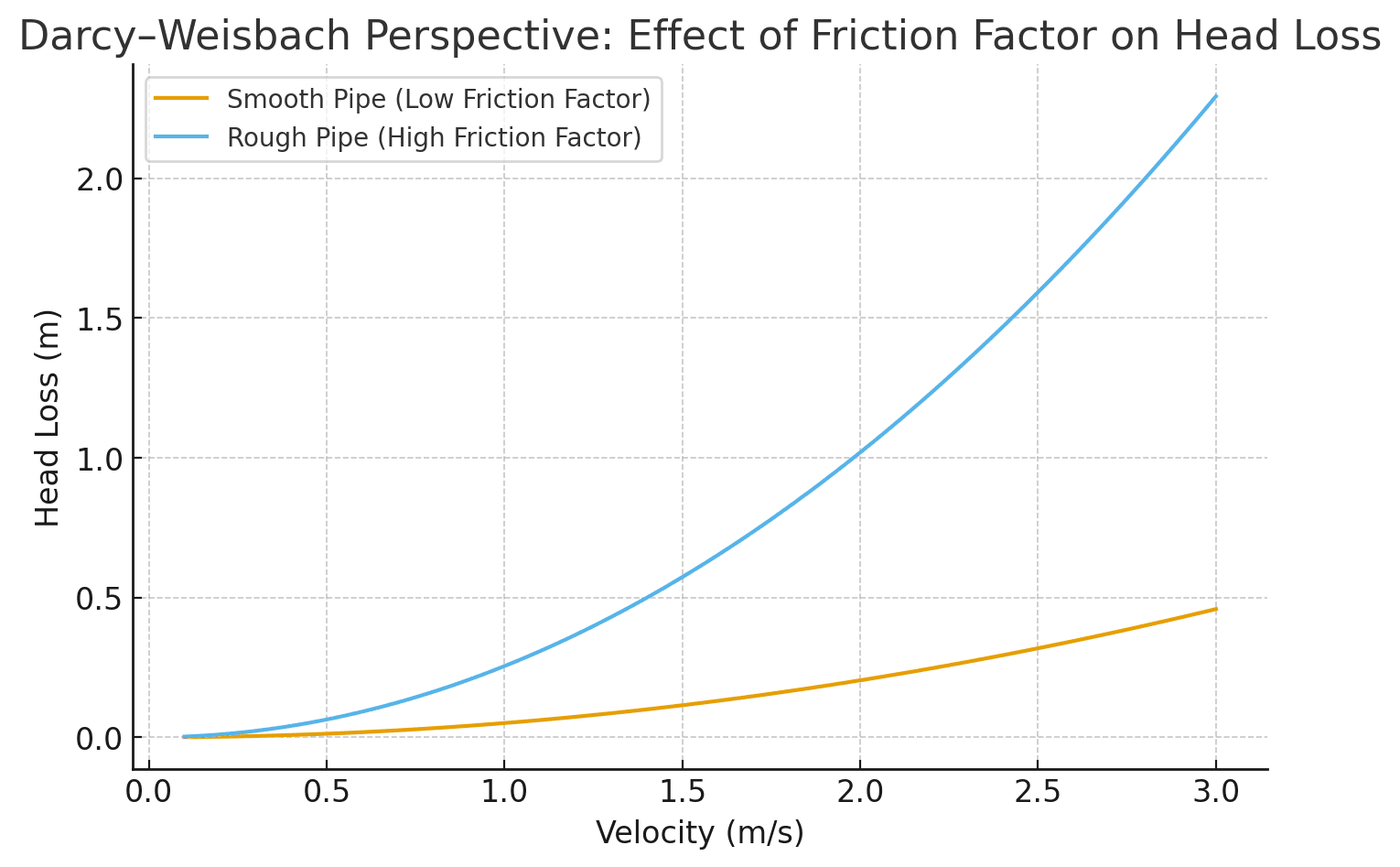

This article explores why a smaller diameter can still deliver a more efficient hydraulic response, how the Lower Friction Factor (as defined by the Darcy–Weisbach equation) affects performance, and why this principle is particularly relevant for the complex culvert estate across the rail network.

On the surface, reducing a culvert’s internal diameter seems like it should reduce capacity. However, when an aged asset is rehabilitated using modern materials such as HDPE, GRP or polymer-coated steel, the internal surface becomes significantly smoother.

hₗ = f × (L/D) × (V² / 2g)

hₗ = head loss

f = Darcy friction factor

L = length

D = hydraulic diameter

V = velocity

g = gravitational acceleration

The critical variable here is the friction factor, f, which is directly influenced by the internal roughness of the culvert wall.

Modern lining systems dramatically lower the friction factor compared to:

So although D reduces slightly, the reduction in f is often far more significant. In most practical culvert rehabilitation cases, the smoother bore reduces energy losses enough to achieve equal or improved conveyance.

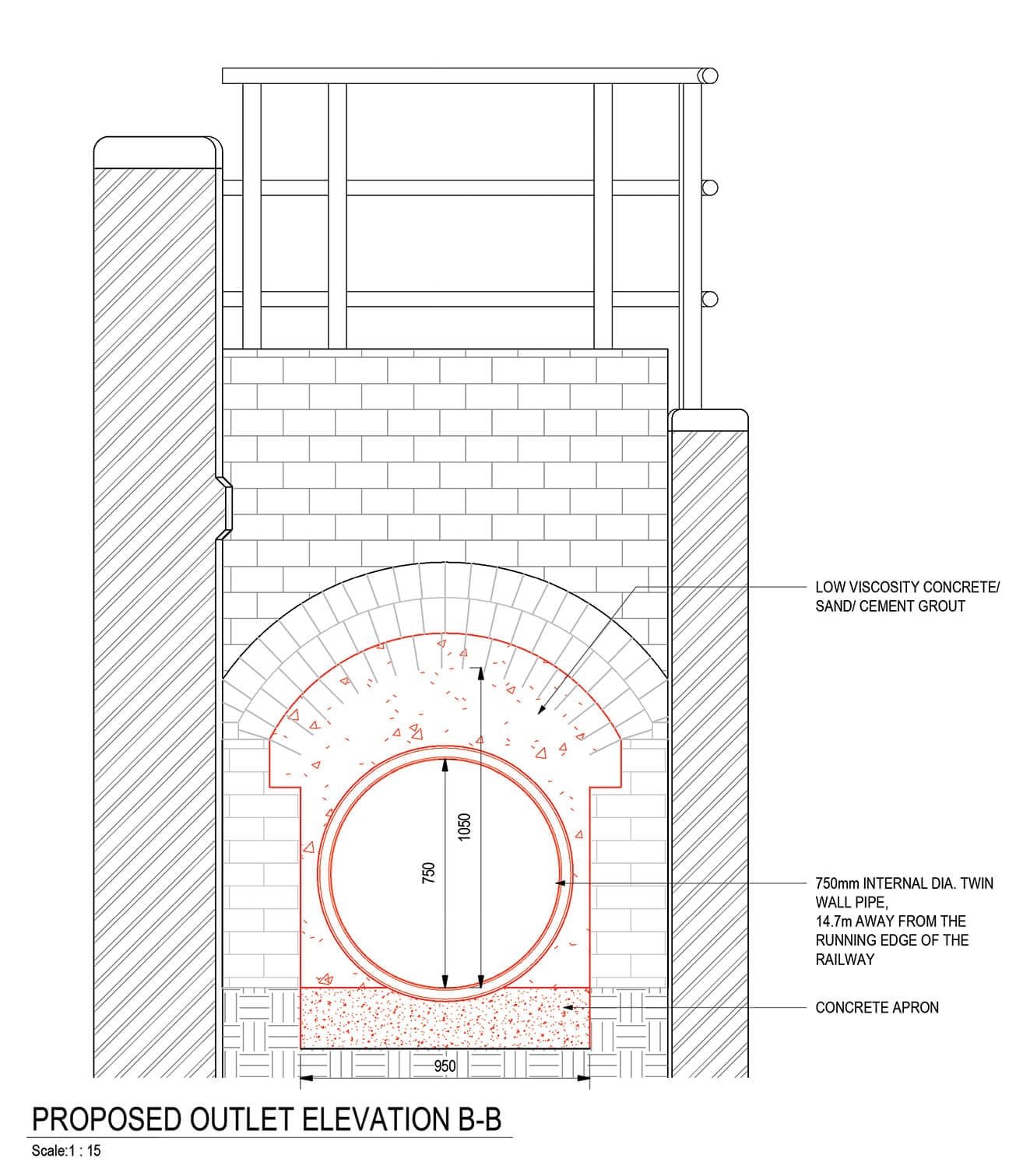

Network Rail inherits a vast range of culvert types, from Victorian masonry arches to concrete pipes, corrugated steel units and bespoke structures formed during railway construction phases more than a century ago. Many of these have become rough, sedimented or partially collapsed, leading to large increases in turbulence and hydraulic energy loss.

When a culvert is relined:

A perfectly circular or regular hydraulic profile is restored.

The interior becomes uniform, eliminating joints and protrusions.

Velocity becomes more stable, reducing areas of local scour.

Debris is less likely to be trapped due to the smoother flow path.

This is precisely the behaviour Network Rail seeks when designing repairs to reduce flooding risk, improve diversionary route resilience, and ensure reliable drainage in cuttings, embankments and beneath formation layers.

Slip-lining aligns with Network Rail’s priorities:

Smooth, regular internal surfaces allow more reliable flow calculations, essential for drainage catchment modelling and flood-risk evaluation.

While counter-intuitive, culvert repairs that reduce diameter can genuinely enhance hydraulic performance. The key factor is the significant reduction in hydraulic roughness, yielding a far lower Darcy–Weisbach friction factor. This lowers head loss and increases the efficiency of the flow path.

For Network Rail assets, many of which are aged, rough and geometrically irregular, this principle is especially valuable. By adopting modern, smooth lining systems, the rail drainage estate gains measurable improvements in reliability, resilience and long-term flow performance, even when the internal diameter becomes marginally smaller.

Please fill in the form and we will get back to you as soon as possible to discuss your new project.

In an age where infrastructure is ageing and maintenance budgets are tightening, asset owners are

Read More >>

Transformer bund fire walls rarely get the attention they deserve, until something goes wrong. These

Read More >>

When culverts reach the end of their service life, one of the most common intervention

Read More >>